-

İskenderGüvenilir tedarikçiler

İskenderGüvenilir tedarikçiler -

LouisSizinle çalışmak bir zevkti.

LouisSizinle çalışmak bir zevkti.

Endüstriyel Kullanım İçin 1 Yıl Garantili Odun Yakıtlı Taşınabilir Buhar Kazanı Ekonomizörü

Ücretsiz numuneler ve kuponlar için bana ulaşın.

whatsapp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Eğer herhangi bir endişeniz varsa, 24 saat online yardım sağlıyoruz.

x| Tip | Doğal Dolaşım | Yapı | Ateş tüpü ve su tüpü |

|---|---|---|---|

| Basınç | Düşük / Yüksek Basınç | Stil | Dikey |

| Yakıt | Kömür yakıtlı | Çıktı | Sıcak Su / Buhar |

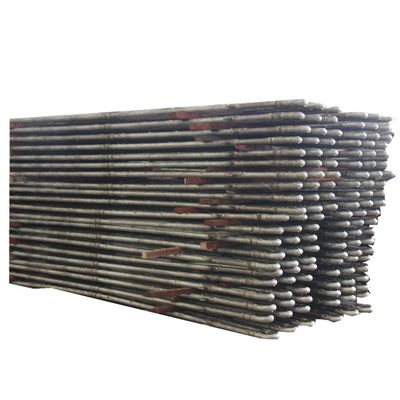

| Yüzey tedavisi | Boyalı | Çıplak boru | 25-1650 mm |

| Çıplak boru kalınlığı | 2-40 mm | Yüzgeç kalınlığı | 0,6-3,0 mm |

| Fin yüksekliği | 5-30 mm | Fin tüp sahası | 5-30 mm |

| Fin tüp uzunluğu | ≤12000 mm | Malzeme | Karbon çelik, alaşım, östenitik çelik |

| Baca gazı hızı | İzin Verilen Maksimum | ||

| Vurgulamak | Odun Yakıtlı Ekonomizör,Taşınabilir Buhar Kazanı Ekonomizörü,1 Yıl Garantili Ekonomizör |

||

Ekonomizör, baca gazından atmosfere atılmadan önce düşük seviyeli enerjiyi geri kazanarak genel kazan termal verimliliğini artırmada çok önemli bir rol oynar. Bu enerji geri kazanımı, kazan besleme suyunun ısıtılması yoluyla gerçekleşir. Ekonomizörler, baca gazından ekstra enerji geri kazanarak işletme maliyetlerini önemli ölçüde azaltan, kazan besleme suyunu buhar tamburuna veya fırın yüzeylerine girmeden önce önceden ısıtan boru şeklindeki ısı transfer yüzeyleridir.

Ekonomizörler, besleme suyu tambura veya su duvarlarına girerken termal şok risklerini ve su sıcaklığı dalgalanmalarını en aza indirir. Ayrıca, azot oksit ve kükürt dioksit emisyonlarını sınırlayan giderek katılaşan çevre düzenlemelerine de uyum sağlarlar. Tasarım, ısı transfer alanını artıran kanatlı dış boru yüzeyleri aracılığıyla, su tarafına kıyasla daha düşük gaz tarafı ısı transfer katsayısını telafi eder. Birincil tasarım hedefi, baca gazı hızı önemli bir kriter olmak üzere, minimum maliyetle gerekli ısı transferini sağlamaktır - daha yüksek hızlar ısı transferini iyileştirir ve sermaye maliyetlerini düşürür.

| Adı (birim) | Özellik (mm) |

|---|---|

| Çıplak boru (OD) | 25-1650 |

| Çıplak boru (Kalınlık) | 2-40 |

| Kanat (Kalınlık) | 0.6-3.0 |

| Kanat (Yükseklik) | 5-30 |

| Kanat borusu diş aralığı | 5-30 |

| Kanat borusu uzunluğu | ≤12000 |

Malzeme:Karbon Çeliği, Alaşım, Östenitik Çelik (Nikel ve Krom veya Manganez)

- Uygulanan malzeme bilgileri ile darbe testi ve mukavemet hesaplama raporu

- Çelik levha, boru ve elektrotun %100 tahribatsız muayene (NDT) raporu

- Tam kazan kalitesini sağlamak için kaynak dikişinin X-ışını, γ-ışını ve sıvı penetrant testi muayene raporu

- Standart çalışma basıncını ve güvenliği doğrulamak için hidrolik test raporu