-

İskenderGüvenilir tedarikçiler

İskenderGüvenilir tedarikçiler -

LouisSizinle çalışmak bir zevkti.

LouisSizinle çalışmak bir zevkti.

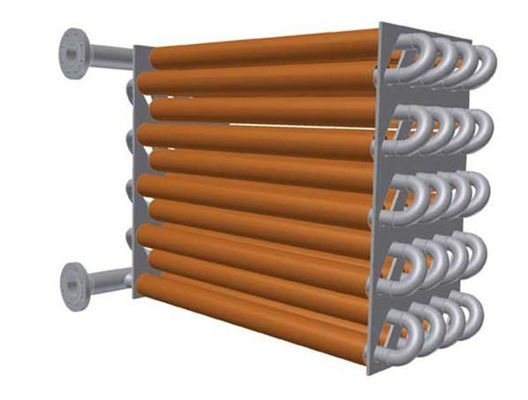

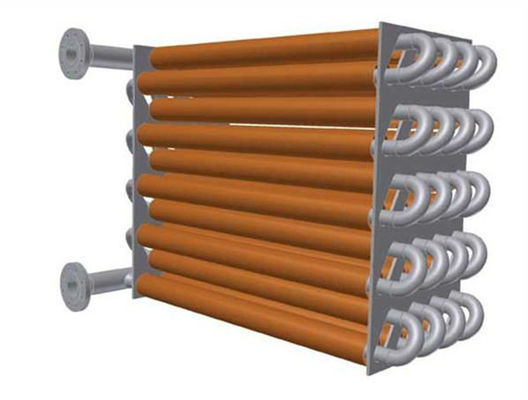

Maks. 120t/h Buhar Üretimi ve 1 Yıl Garantili, Doğal Sirkülasyonlu, Kanatlı Borulu Baca Gazı Kazanı Ekonomizörü

Ücretsiz numuneler ve kuponlar için bana ulaşın.

whatsapp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Eğer herhangi bir endişeniz varsa, 24 saat online yardım sağlıyoruz.

x| Tip | Doğal Dolaşım | Yapı | Ateş tüpü ve su tüpü |

|---|---|---|---|

| Basınç | Düşük / Yüksek Basınç | Buhar Üretimi | Maks. 120t/s |

| Stil | Dikey | Yakıt | Kömür / Gaz / Kömürle çalışan / Su ısısı |

| Çıktı | Sıcak Su / Buhar | Malzeme | Karbon çelik, paslanmaz çelik, alaşım çelik |

| Malzeme Standardı | ASTM, EN veya ISO vb. | ağırlık aralığı | Min: 10 ton maksimum .:1000 ton |

| Eritme işlemi | EF+LF + VD | İşlem | Malzeme-> Ingot -> Sıcak/Soğuk Alma-> Isı Tedavisi (Normalleştirme+ Temperleme) -> Muaye |

| UT standardı | ASTM A388 veya EN10228, vb. | Isı Eşanjörü Türü | H yüzgeçli tüp ekonomizer |

| Tüp tipi | Çift H Yüzlü Tüpler | ||

| Vurgulamak | Maks. 120t/h Buhar Üretimi Kazan Ekonomizörü,1 Yıl Garantili Isı Eşanjörü,Doğal Sirkülasyonlu Baca Gazı Ekonomizörü |

||

Kazana ekonomizörleri, sıvıları (tipik olarak su) kaynama noktalarını aşmadan ısıtmak için tasarlanmış, finned tüplere sahip yüksek verimli ısı eşanjörleridir. Üç tip kazan ekonomizörü üretiyoruz:

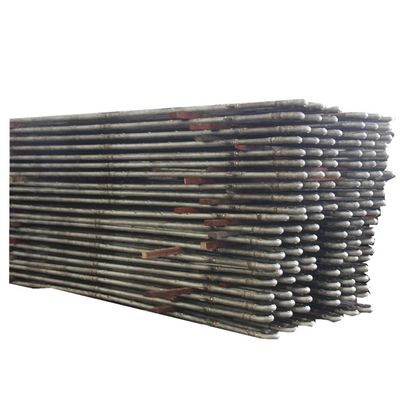

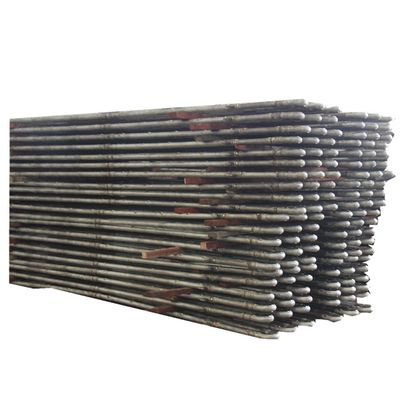

- Çıplak borulu ekonomizör

- H-finned borulu ekonomizör

- Spiral finned borulu ekonomizör

H-finned borulu ekonomizör, H-finned borulardan oluşan özellikle verimli bir tasarımdır. Çıplak borulu ekonomizörlere kıyasla, H-finned boru modelleri çeşitli avantajlar sunar:

- Artırılmış ısı alışveriş alanı

- Gerekli boru sayısının azaltılması

- Akış hızını ve aşınmayı azaltmak için genişletilmiş baca gazı akış alanı

- Uzun boru sıralarında gelişmiş sağlamlık için çift H-finned boru konfigürasyonunda mevcuttur

Spiral finned ekonomizör, aşınma sorunlarını etkili bir şekilde ele alan ve hizmet ömrünü uzatan spiral fin tüpler içeren en son tasarım yeniliğimizi temsil eder.

| Tanım | Kazan ekonomizörü |

|---|---|

| Malzeme | Alaşımlı çelik, Karbon çeliği, SA210C, SA213T22, vb. |

| Malzeme standardı | ASTM, EN veya ISO vb. |

| Boyut | Özelleştirme |

| Ağırlık | Min: 10 ton Maks.:1000 ton |

| Ergitme İşlemi | EF+LF + VD |

| Süreç | Malzeme→Külçe → Sıcak/Soğuk Haddelenme→ Isıl işlem (Normalleştirme+ temperleme) → Muayene →kaba işleme→UT →2. Isıl işlem →finishing işleme →Muayene |

| UT standardı | ASTM A388 veya EN10228, vb. |

- Uygulanan malzeme bilgileri ile birlikte darbe testi ve Mukavemet hesaplama raporu

- Çelik levha, boru ve elektrotun %100 tahribatsız muayene (NDT) raporu

- Tam kazan kalitesini sağlamak için X-ışını, γ-ışını ve sıvı penetrant testi muayene raporu (kaynak dikişi)

- Standart çalışma basıncını ve güvenliği doğrulamak için hidrolik test raporu